C51000 C51000 Phosphor Bronze 5% A, cast and cold drawn. Excellent soldering and brazing capability. Corrosion resistant.

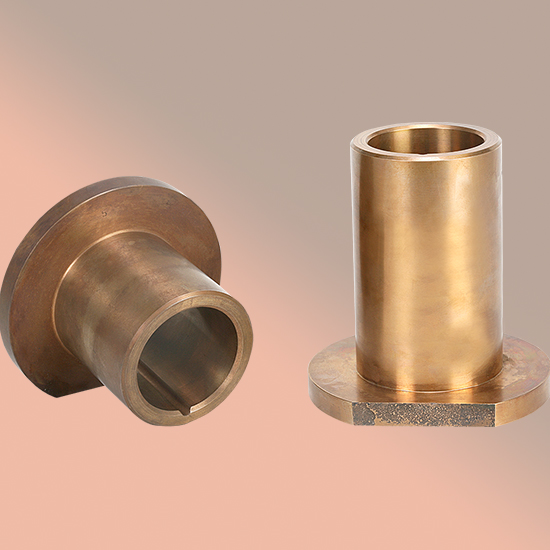

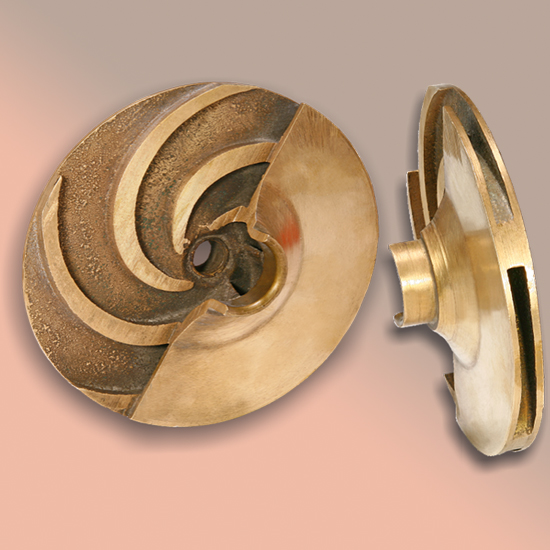

Phosphorus Bronze Castings

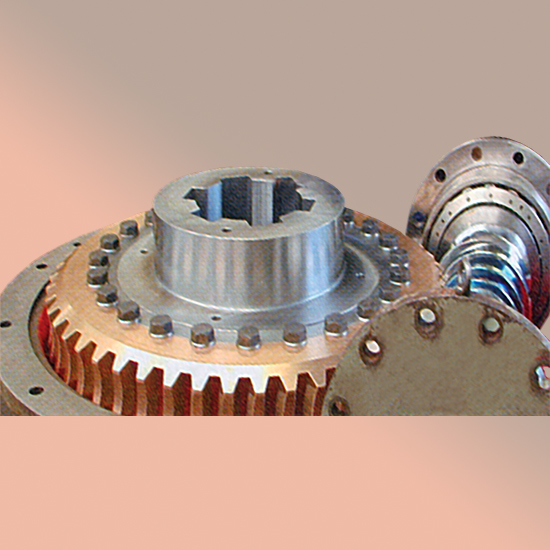

Phosphor bronzes are wrought alloys containing copper, tin and phosphorous. The addition of tin increases the corrosion resistance and strength of the alloy and the addition of phosphorous increases its wear resistance and stiffness. Phosphor bronzes have superb spring qualities, high fatigue resistance, excellent formability, solderability, and high corrosion resistance. Leaded phosphor bronzes offer good strength, machinability, high wear resistance and corrosion resistance.

| Available AlloysShow All / Hide All | ||

|---|---|---|

| FAMILY | ALLOY | DESCRIPTION |

| Phosphor Bronze | C51000 Phosphor Bronze 5% Ahide | Phosphor Bronze, is the most widely used of the phosphor bronze alloys. C51000 offers high strength and ductility, superior fatigue and spring characteristics, excellent corrosion resistance, durability for severe service, good bearing qualities with low friction and higher wear resistance, superior forming and spinning, resistance to stress relaxation and good joining properties. |

| C54400 Phosphor Bronze B-2 | Phosphor Bronze is an excellent bearing alloy, and exhibits very good machinability due to its lead content. The alloy has excellent spring properties, and is used for electrical contacts, and can be work-hardened. When annealed, this metal can be bent, formed, blanked, and stamped. | |